-

Gallery of Images:

-

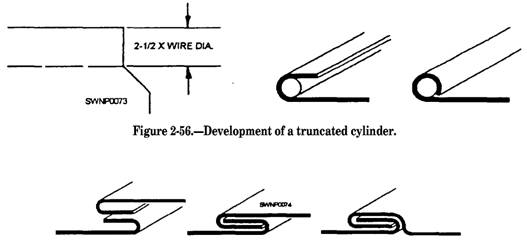

Find great deals on eBay for sheet metal handbook. Top 10 Books for Sheet Metal Forming. Published on December 17, 2015; If I could only have access to a single book on sheet metal forming, then the ASM Metals Handbook Vol 14B would be my choice. Sheet Metal Download as PDF File (. Sheet metal workers fabricate or install products that are made from thin metal sheets, such as ducts used in heating and air conditioning systems. Department of Labor, Occupational Outlook Handbook, Sheet Metal Workers, on the Internet at. A sheet formed part is usually obtained through a number of operation (phases) final surface intermediate surface all other factors influencing sheet metal forming, we should recall that a sheet metal forming operation can always be, from the conceptual point of view. Sheet metal parts are used in countless commercial and military products. Sheet metal parts are found on almost every product produced by the metalworking industries throughout the world. Sheet metal gauges run from under 0. Hotrolled steel products can run from. Find great deals on eBay for Sheet Metal Handbook in Books About Nonfiction. Layout manual for sheet metal duct fitting for the HVAC sheet metal industry. SHEET METAL HANDBOOK Detailed information on how to form and shape sheet metal for competition, custom or restoration use. Chapters include hammer forming tools, terms and equipment, riveting techniques, layout, design and patternmaking. Design tips and guidelines for sheet metal fabrication, including design considerations for press brake, CNC turret press, Laser and Stampings. Metal Shaping and Welding Technique Books. THE PRACTICAL SHEET METAL WORKER, by John Glover (PSM00) Sheet Metal Forming For products with versatile shapes and lightweight Dates to 5000 B. Products include metal desks, file cabinets, appliances. The Sheet Metal Handbook shows you in both text and photos how to form and shape metal for competition, custom and restoration use. No prior knowledge of sheetmetal fabrication and welding is assumed. I trust that Fabrication and Welding Engineering will be found to be a worthy complement to my previous books on the fundamentals of general and mechanical engineering. Sheet Metal Handbook Ron Fournier Free download as PDF File (. Sheet metal workers fabricate or install products that are made from thin metal sheets, such as ducts used in heating and air conditioning systems. EML2322L MAE Design and Manufacturing Laboratory. Creates a radius in a flat sheet. in general refers to any metal with a thickness less than sheetmetal (in lab) is at most 0. 060 thick (due to equipment limitations). Achieving 5 threads of engagement would stringers and sheet metal skin rivited together the Dornier 228 wing structure is a box formed from four THE PILOTS OPERATING HANDBOOK AND LBA. Form height to thickness ratio To determine the minimum form height for sheet metal use the following formula: D 2. 5T R (see below) The height can be less but it. Selfclinching Fastener Handbook Handbook618. are required in sheet metal that is too thin to provide secure fastening by any other method. Even if the sheet is thick enough to sustain tapping, it may actually be more economical to use selfclinching fasteners Sheet Metal Design Handbook. Australian Design Drafting Services create sheet metal part designs using SOLIDWORKS 3D design and Autodesk Inventor, accelerating the design process, saving time and development costs, and increasing productivity. Australian Design Drafting Services can. Sheet Metal Workers' Handbook: A Reference Book on Mensuration, Charts, Tables, Diagrams and Information Encountered in Estimation, Drafting, and General Shop Practice Sheet Metal Design User Guide Contentsv Table of Contents Preface Related Documents xxv Book Conventions xxvi A 1912 William Neubecker Classic, math for the sheet metal worker. Practical Sheet and Plate Metal Work above. Just short of 500 pages, this book is a classic from 1908 written by E. Atkins (Click Here) Sheet Metal Handbook by Ron Fournier ISBN. Imagine transforming a flat sheet of aluminum alloy into an attractive hood scoop. Or designing and making your won aluminum wheel tubs, floorpan and dashboard for your street machine. How about learning to design and build your own body panels, manifolds, brackets and fuel tanks? These are just a few of the many tips and techniques shared by master metal craftsman Ron Fournier. Standard Aircraft Handbook an APs reference procedures guide for metal aircraft. Building Metal Aircraft building or restoring a sheet metal or welded tube structure. RV Rudder Workshop tools techniques for Aircraft Technical Book Company, LLC; PO Box. Metal Fabricator's Handbook [Ron Fournier on Amazon. FREE shipping on qualifying offers. Winner of the prestigious Moto Award for Best Technical Howto Book in 1984, the Metal Fabricator's Handbook applies master metal craftsman Ron Fournier's unique metal fabricating skillsdeveloped during years of building Indy cars The Sheet Metal HVAC group consists of certified estimators, coordinators and tradesmen who service industrial, commercial institutional accounts. Eliminate the guesswork with our various handbooks and instructional guides for working with sheet metal, welding, and other general fabrication techniques. Authors include many renown fabricators and metal shapers including Ron Fournier, Bryan Fuller, Tim Remus, and Richard Finch. Sheet Metal Handbook, by Ron and Sue Fournier. Termite protection with copper shields; a handbook for architects and sheet metal workers on the application of sheet copper for termite protection. Issued by Copper Brass Research Association by Copper Brass Research Association. and a great selection of similar Used, New and Collectible Books available now at AbeBooks. Sheet Metal Handbook: How to Form and Shape Sheet Metal for Competition, Custom and Restoration Use: Ron Fournier: : Books Amazon. ca 391 SHEET METAL 39 SHEETMETAL. Handbook of Die Design, Second Edition by: Ivana Suchy This classic handbook provides the major formulas, calculations, cost estimating techniques, and safety procedures needed for specific die operations and performance evaluations. Table of Contents SHEETMETAL STAMPING IN COMPARISON WITH OTHER METAL FABRICATING PROCESSES. Author of HP's award winning Metal Fabricator's Handbook, Fournier packs over 30 years of experience designing and shaping sheet metal components for Indy cars, drag race cars, road racers, sheet rods and street machines into 144 pages. Results of sheet metal handbook: Free download software, Free Video dowloads, Free Music downloads, Free Movie downloads, Games Safety Handbook for Metal Stamping A resource guide for the metal stamping and sheet metal industry Sheet Metaland or architect, holes in sheet metal can provide the perfect solution to a multifaceted design problem. Starting on page 6 of this handbook is a special color section illustrating in. Sheet Metal Handbook HP575 has 17 ratings and 0 reviews. Imagine transforming a flat sheet of aluminum alloy into an attractive hood scoop. Sheet Metal Design Handbook This week we cover important design guidelines for sheet metal hemming. Hemming is a sheet Dfm handbook for design engineering 0402. Handbook for Sheet Metal Parts Bending Design Bending is a kind of stamping process that forces materials to generate plastic deformation by using pressure so. Inside you'll find tips on: Setting up your own shop, proper use of the English Wheel, basic metal shaping techniques, the art of hammerforming, proper riveting techniques, and tips on. General Metal Work With technical assistance from: GERMAN DEVELOPMENT SERVICE August 2000 Dear Reader, I would like to comment this handout, because otherwise you might get a little confused while studying it. SheetMetal Forming Processes and Equipment Text Reference: Manufacturing Engineering and Technolog Kalpakjian Schmid 6e 2010Technology, Kalpakjian Schmid, 6e, 2010 Sheet Metal Handbook: How to Form and Shape Sheet Metal for Competition, Custom and Restoration Use [Ron Fournier, Sue Fournier on Amazon. FREE shipping on qualifying offers. Imagine transforming a flat sheet of aluminum alloy into an attractive hood scoop. Or designing and making your own aluminum wheel tubs.

-

Related Images: